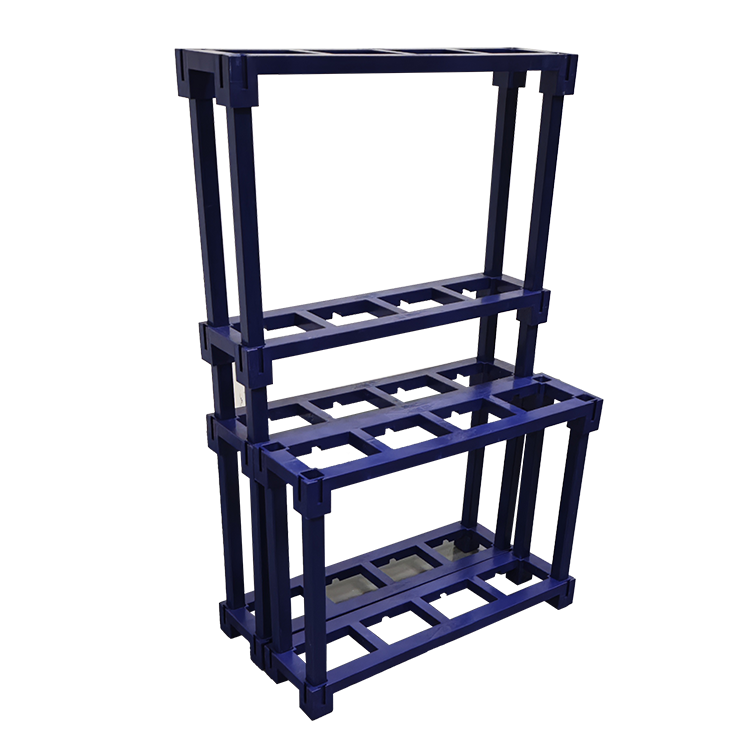

floor display stands mold

Floor display stands molds represent a crucial manufacturing tool in the retail display industry, engineered to create versatile and eye-catching point-of-purchase displays. These precision-engineered molds are designed to produce durable, aesthetically pleasing display stands that effectively showcase products in retail environments. The molds incorporate advanced injection molding technology, featuring carefully calculated gates, runners, and cooling channels to ensure consistent production quality. They are typically constructed from high-grade tool steel, capable of withstanding high pressure and repeated use while maintaining dimensional accuracy. The mold design accommodates various display stand configurations, from simple single-piece structures to complex multi-component assemblies. These molds often feature interchangeable components, allowing for quick modifications to meet different display requirements. The manufacturing process includes sophisticated temperature control systems and pressure monitoring mechanisms to guarantee optimal material flow and product consistency. Modern floor display stands molds also integrate smart design elements that facilitate easy assembly and disassembly of the final products, making them practical for both manufacturers and end-users.