كم تبلغ تكلفة شاشة العرض البلاستيكية من نوع POP؟ تحليل السعر حسب الحجم والكمية

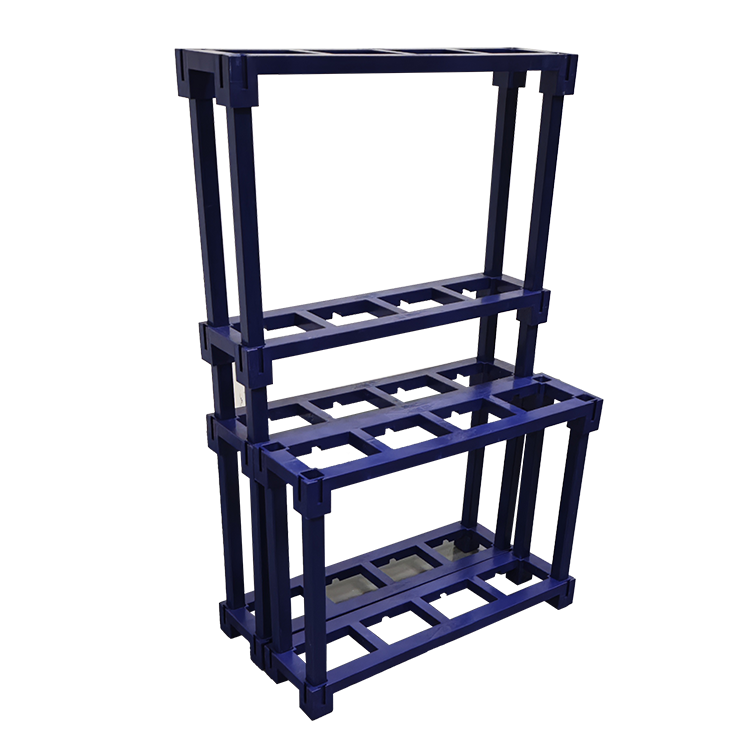

فهم مكونات التكلفة في حلول عروض البيع بالتجزئة من حيث الترويج الفعال للمنتجات في نقطة البيع، تظل عروض البلاستيك المرورية واحدة من أكثر الحلول تنوعاً وفعالية من حيث التكلفة المتاحة. الاستثمار في ...

عرض المزيد