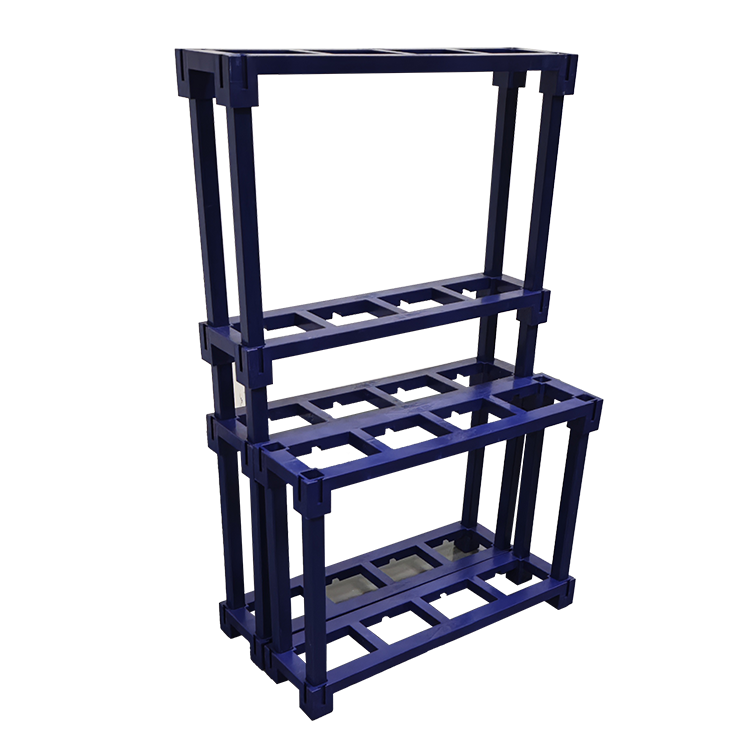

cheap retail display racks mold

The cheap retail display racks mold represents a cost-effective solution for businesses seeking to manufacture custom retail display systems. This versatile mold system incorporates advanced injection molding technology, enabling the production of durable, lightweight display racks suitable for various retail environments. The mold features precision-engineered cavities that ensure consistent quality and dimensional accuracy across production runs, while its modular design allows for quick changeovers and adaptable configurations. The mold's construction utilizes high-grade steel materials, treated with specialized surface hardening processes to ensure longevity and wear resistance. It accommodates various thermoplastic materials, including ABS, PP, and PE, making it suitable for producing display racks with different characteristics and applications. The mold's cooling system is optimized for rapid cycle times, featuring strategically placed cooling channels that maintain uniform temperature distribution and prevent warping. Additionally, the design incorporates easy-release mechanisms and minimal flash formation, reducing post-processing requirements and overall production costs.