Retail environments are increasingly competitive, making point-of-purchase displays critical for capturing customer attention and driving sales conversions. Selecting the right retail POP display supplier can significantly impact your merchandising success, brand visibility, and overall return on investment. Understanding the key factors involved in sourcing these display solutions requires comprehensive knowledge of manufacturing capabilities, design expertise, and industry standards that distinguish professional suppliers from generic providers.

Modern retail spaces demand display solutions that seamlessly integrate functionality with aesthetic appeal. Professional suppliers understand that effective point-of-purchase displays must enhance product visibility while maintaining structural integrity under constant customer interaction. This comprehensive approach to display manufacturing ensures that retailers receive solutions designed for both immediate impact and long-term durability in high-traffic environments.

Understanding Retail POP Display Manufacturing Excellence

Material Selection and Quality Standards

Premium retail display manufacturing begins with strategic material selection that balances cost-effectiveness with performance requirements. Professional suppliers utilize high-grade plastics, metals, and composite materials specifically engineered for retail environments. These materials undergo rigorous testing to ensure they withstand daily wear, maintain color stability under various lighting conditions, and resist impact damage from customer handling.

Quality control processes implemented by leading manufacturers include dimensional accuracy verification, stress testing, and surface finish inspections. Advanced suppliers maintain ISO certification standards and implement continuous improvement protocols that ensure consistent product quality across large production runs. Understanding these manufacturing standards helps retailers evaluate potential suppliers based on their commitment to quality excellence rather than solely on price considerations.

Design Innovation and Customization Capabilities

Successful retail displays require sophisticated design engineering that considers product dimensions, weight distribution, assembly requirements, and visual impact factors. Leading suppliers invest in advanced CAD software, prototyping equipment, and design teams with extensive retail merchandising experience. This technical infrastructure enables rapid design iteration and customization that addresses specific brand requirements and retail space constraints.

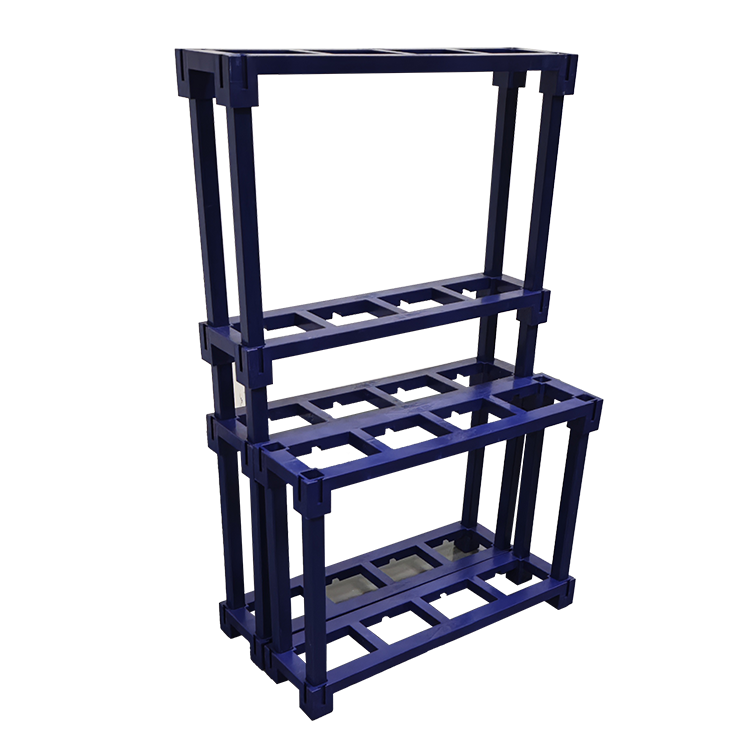

Modern display design incorporates modular concepts that allow retailers to reconfigure displays for different products or seasonal promotions. Professional suppliers offer comprehensive design services including 3D visualization, structural analysis, and prototype development that ensure final products meet both aesthetic expectations and functional requirements before full production begins.

Strategic Sourcing Considerations for Retail Displays

Production Capacity and Scalability Assessment

Evaluating a retail POP display supplier requires thorough assessment of their production capabilities, facility capacity, and ability to scale operations according to changing demand patterns. Professional manufacturers maintain multiple production lines with redundant capacity to handle seasonal fluctuations and unexpected order increases without compromising delivery schedules or quality standards.

Advanced suppliers implement lean manufacturing principles and maintain strategic inventory levels of raw materials to ensure rapid response to urgent requests. Their production planning systems integrate demand forecasting with capacity optimization to minimize lead times while maintaining cost efficiency. This operational sophistication distinguishes professional suppliers from smaller manufacturers who may struggle with consistency during peak demand periods.

Global Supply Chain Management

International retail operations require suppliers with sophisticated logistics capabilities and global distribution networks. Leading manufacturers maintain strategically located facilities that enable regional production and reduce shipping costs while providing faster delivery times. Their supply chain management systems integrate inventory tracking, quality assurance, and logistics coordination across multiple locations.

Professional suppliers also maintain compliance with international trade regulations, product safety standards, and environmental requirements across different markets. This regulatory expertise ensures that retail displays meet local requirements without delays or additional certification costs that could impact project timelines or budget constraints.

Technical Specifications and Performance Criteria

Structural Engineering and Load Capacity

Retail display engineering requires precise calculation of load-bearing capacity, structural stability, and safety factors under various loading conditions. Professional suppliers employ structural engineers who design displays capable of supporting maximum product loads while maintaining stability during customer interaction. These calculations include dynamic loading scenarios, environmental factors, and safety margins that exceed minimum requirements.

Advanced testing protocols verify structural performance through computer simulation and physical testing that replicates real-world conditions. Suppliers document these test results and provide certification that displays meet or exceed industry safety standards. This technical documentation proves essential for retailers operating in regulated environments or managing liability concerns related to display safety.

Assembly and Installation Requirements

Efficient display deployment requires careful consideration of assembly complexity, installation time, and skill requirements for retail staff. Leading suppliers design displays with intuitive assembly processes that minimize installation time while ensuring proper structural integrity. Clear instruction documentation, pre-fitted components, and tool-free assembly options reduce deployment costs and potential assembly errors.

Professional manufacturers provide comprehensive installation support including training materials, video guides, and technical assistance that enable successful deployment across multiple retail locations. Their design philosophy prioritizes ease of assembly without compromising structural performance or aesthetic quality, ensuring that displays function properly regardless of installation skill levels.

Cost Analysis and Value Optimization

Total Cost of Ownership Evaluation

Comprehensive cost analysis extends beyond initial purchase price to include shipping, assembly, maintenance, and replacement costs over the display lifecycle. Professional suppliers provide detailed cost breakdowns that enable accurate total cost of ownership calculations. These analyses consider factors such as durability expectations, maintenance requirements, and potential modification costs for future product changes.

Value optimization requires balancing initial investment with long-term performance expectations and potential return on investment through increased sales performance. Leading suppliers offer various material and design options that enable cost optimization without compromising essential functionality or brand presentation requirements. Their consultative approach helps retailers identify the most cost-effective solutions for specific applications and budget constraints.

Volume Pricing and Partnership Benefits

Establishing strategic partnerships with reliable suppliers can provide significant cost advantages through volume pricing, priority production scheduling, and preferential terms for rush orders. Professional manufacturers offer tiered pricing structures that reward loyalty and provide incentives for consolidating display sourcing with a single supplier. These partnerships often include additional services such as design consultation, inventory management, and logistics support.

Long-term supplier relationships enable collaborative development of custom solutions, shared investment in tooling costs, and coordinated planning that reduces overall project costs. Successful partnerships require clear communication channels, defined performance metrics, and mutual commitment to continuous improvement that benefits both parties through operational efficiency and market responsiveness.

Quality Assurance and Compliance Standards

Manufacturing Quality Control Systems

Professional display manufacturers implement comprehensive quality management systems that encompass incoming material inspection, in-process monitoring, and final product verification. These systems utilize statistical process control methods, automated inspection equipment, and trained quality personnel to ensure consistent product quality. Documentation systems track quality metrics and enable rapid identification of potential issues before they impact production schedules.

Advanced suppliers maintain certification to international quality standards such as ISO 9001 and implement continuous improvement programs that enhance manufacturing processes over time. Their quality systems include supplier qualification programs, regular audits, and corrective action procedures that ensure sustained quality performance throughout the supply chain relationship.

Environmental and Safety Compliance

Modern retail display manufacturing must comply with environmental regulations, safety standards, and sustainability requirements that vary across different markets and applications. Professional suppliers maintain current knowledge of regulatory requirements and implement manufacturing processes that ensure compliance without additional costs or delays. Their material selection processes prioritize environmentally responsible options while maintaining performance requirements.

Safety compliance includes both manufacturing safety protocols and end-user safety considerations such as edge finishing, stability requirements, and material toxicity standards. Leading suppliers provide comprehensive documentation of compliance status and maintain liability insurance coverage that protects retailers from potential safety-related issues during display deployment and operation.

Supplier Evaluation and Selection Process

Capability Assessment Methodology

Systematic supplier evaluation begins with comprehensive assessment of manufacturing capabilities, quality systems, financial stability, and technical expertise. Professional evaluation processes include facility tours, reference checks, sample evaluations, and capability demonstrations that provide objective evidence of supplier performance potential. This thorough assessment prevents costly mistakes and ensures selection of suppliers capable of meeting long-term requirements.

Effective evaluation criteria include production capacity verification, quality certification review, financial stability analysis, and technical capability assessment through sample production or pilot projects. Leading retailers develop standardized evaluation protocols that enable consistent comparison between potential suppliers and objective decision-making based on quantifiable performance criteria rather than subjective impressions or price alone.

Performance Monitoring and Relationship Management

Successful supplier relationships require ongoing performance monitoring through key performance indicators such as delivery performance, quality metrics, responsiveness to issues, and continuous improvement initiatives. Professional suppliers welcome performance monitoring and provide regular reporting that demonstrates their commitment to service excellence and continuous improvement.

Relationship management includes regular business reviews, joint planning sessions, and collaborative problem-solving that strengthens partnerships over time. These activities enable proactive identification of potential issues, joint development of solutions, and alignment of supplier capabilities with evolving retail requirements. Strong supplier relationships provide competitive advantages through preferential treatment, innovation collaboration, and market intelligence sharing.

FAQ

What factors should retailers prioritize when selecting a display supplier

Retailers should prioritize manufacturing quality, design capabilities, production capacity, and total cost of ownership when evaluating potential suppliers. Technical expertise, compliance with safety standards, and ability to provide ongoing support are equally important factors that impact long-term success. Financial stability and references from similar retail operations provide additional confidence in supplier selection decisions.

How can retailers ensure display quality meets their brand standards

Quality assurance requires clear specifications, sample approval processes, and ongoing quality monitoring throughout production. Professional suppliers provide detailed quality documentation, implement statistical process control, and welcome third-party inspections to verify compliance with specifications. Establishing clear quality standards and verification procedures prevents quality issues and ensures displays meet brand presentation requirements.

What are typical lead times for custom retail display production

Custom display lead times typically range from 4-12 weeks depending on complexity, quantity, and supplier capacity. Simple modifications to existing designs may require shorter timeframes, while completely custom solutions with new tooling requirements extend lead times. Professional suppliers provide accurate timeline estimates during the quotation process and maintain communication throughout production to manage expectations and coordinate delivery schedules.

How do retailers manage costs while maintaining display quality standards

Cost management requires balancing initial investment with long-term value through durability, functionality, and brand impact considerations. Professional suppliers offer various material and design options that enable cost optimization without compromising essential requirements. Volume purchasing, strategic partnerships, and standardized designs across multiple locations provide additional cost savings opportunities while maintaining quality standards.