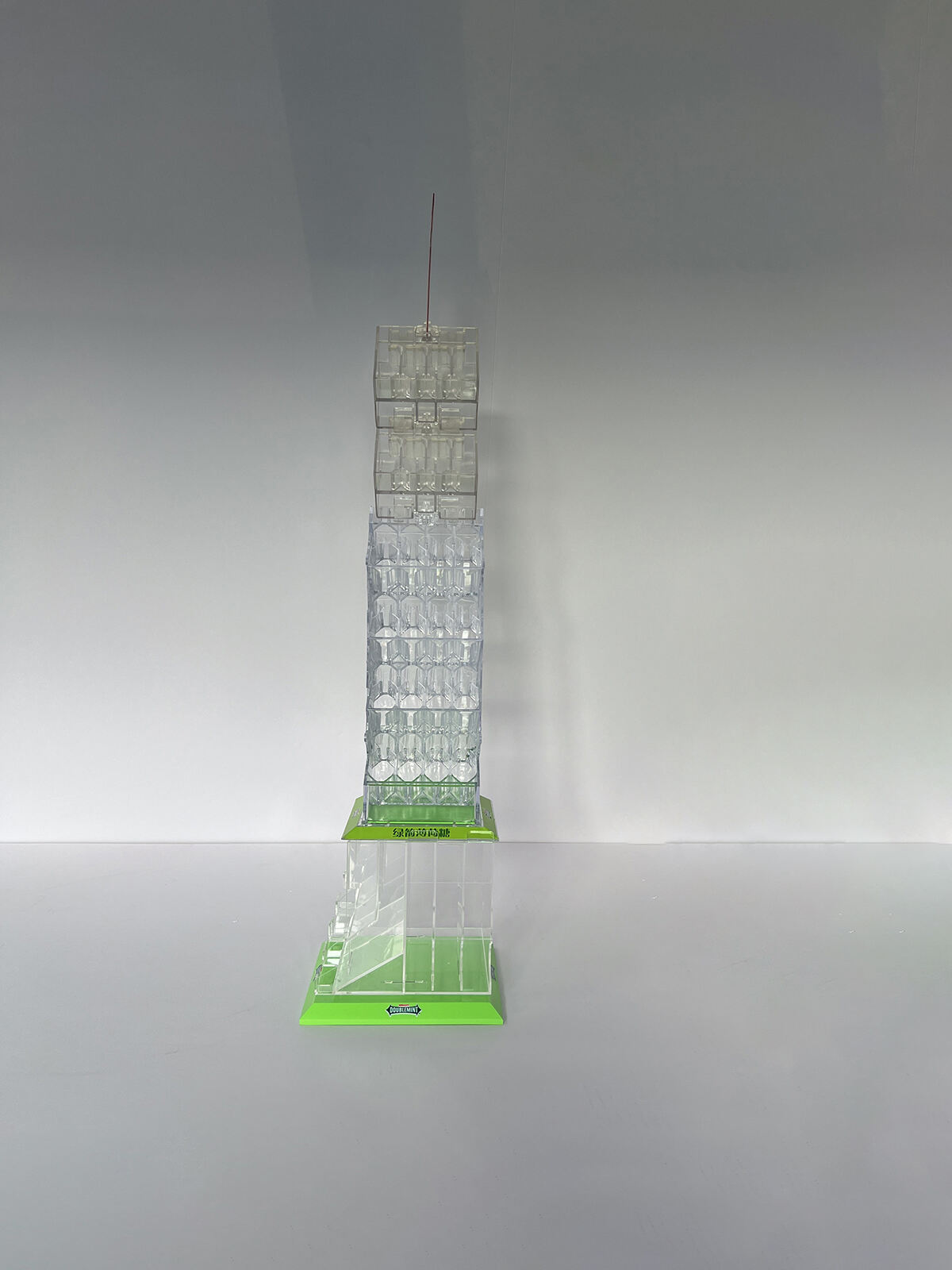

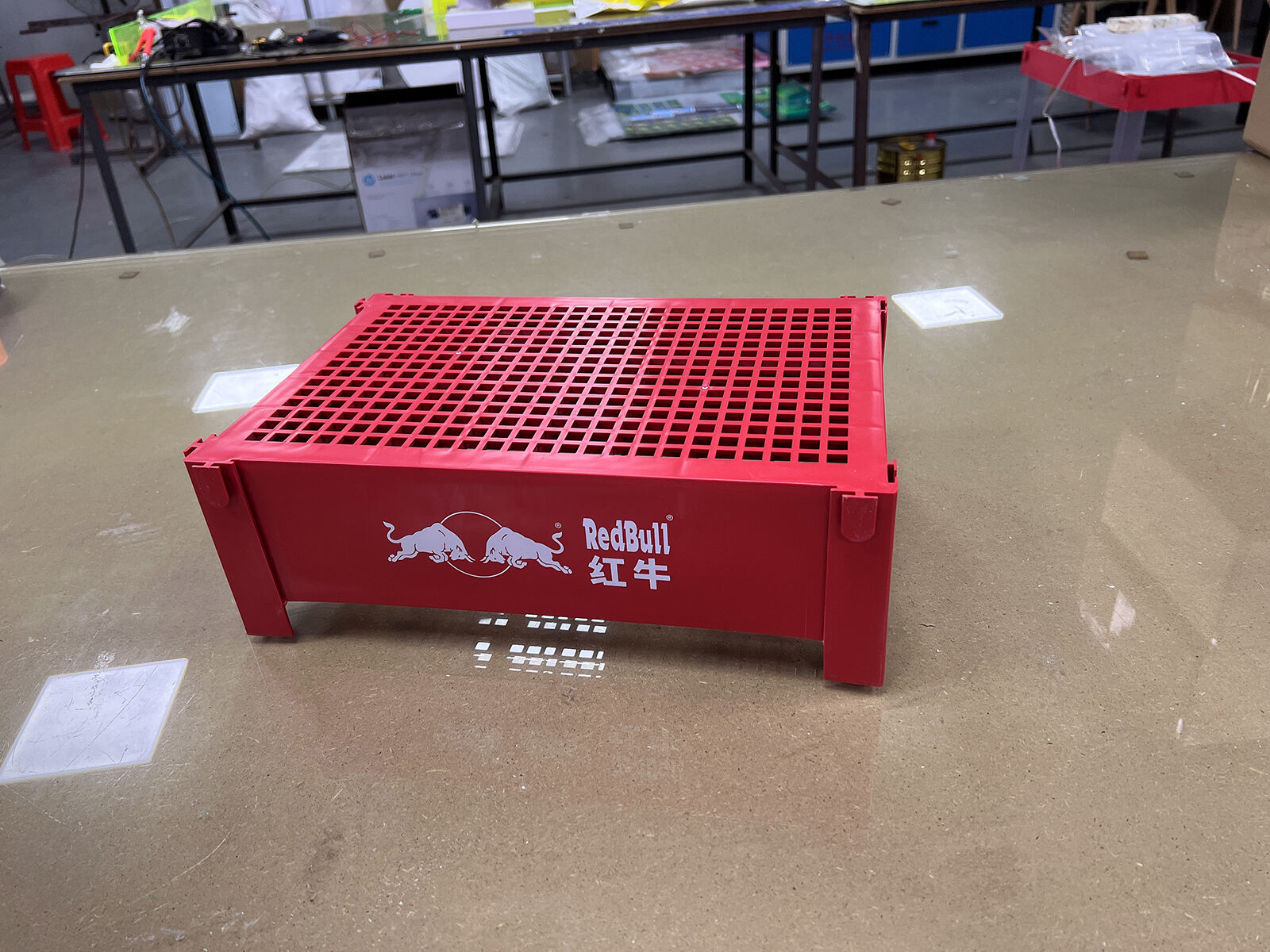

mini display stand mold

The mini display stand mold represents a cutting-edge solution in the retail and exhibition industry, designed to create compact and versatile display stands for various products. This precision-engineered mold combines advanced manufacturing technology with practical functionality, enabling the production of durable, lightweight display stands that maximize visual appeal while minimizing space utilization. The mold features sophisticated cavity designs that ensure consistent product quality, incorporating multiple cooling channels for optimal temperature control during the molding process. Its innovative design allows for quick changeovers and efficient production cycles, making it ideal for both small and large production runs. The mold's versatile nature accommodates various materials, including ABS, PC, and acrylic, ensuring compatibility with different product requirements and aesthetic preferences. With precise dimensional control and superior surface finish capabilities, the mini display stand mold produces stands that meet exact specifications while maintaining aesthetic appeal. The mold's robust construction ensures longevity and reliability, while its modular design facilitates easy maintenance and component replacement when necessary.