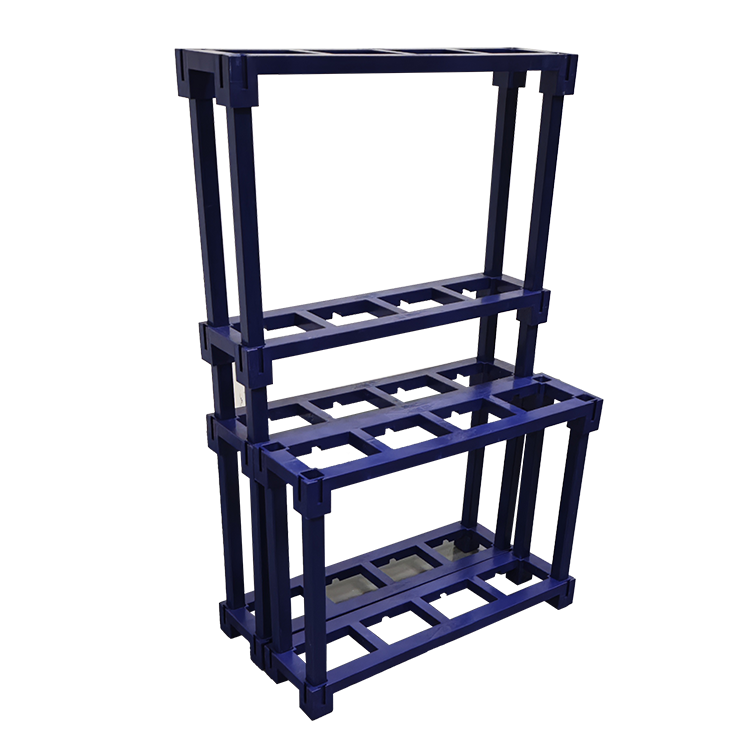

hanging display stand mold

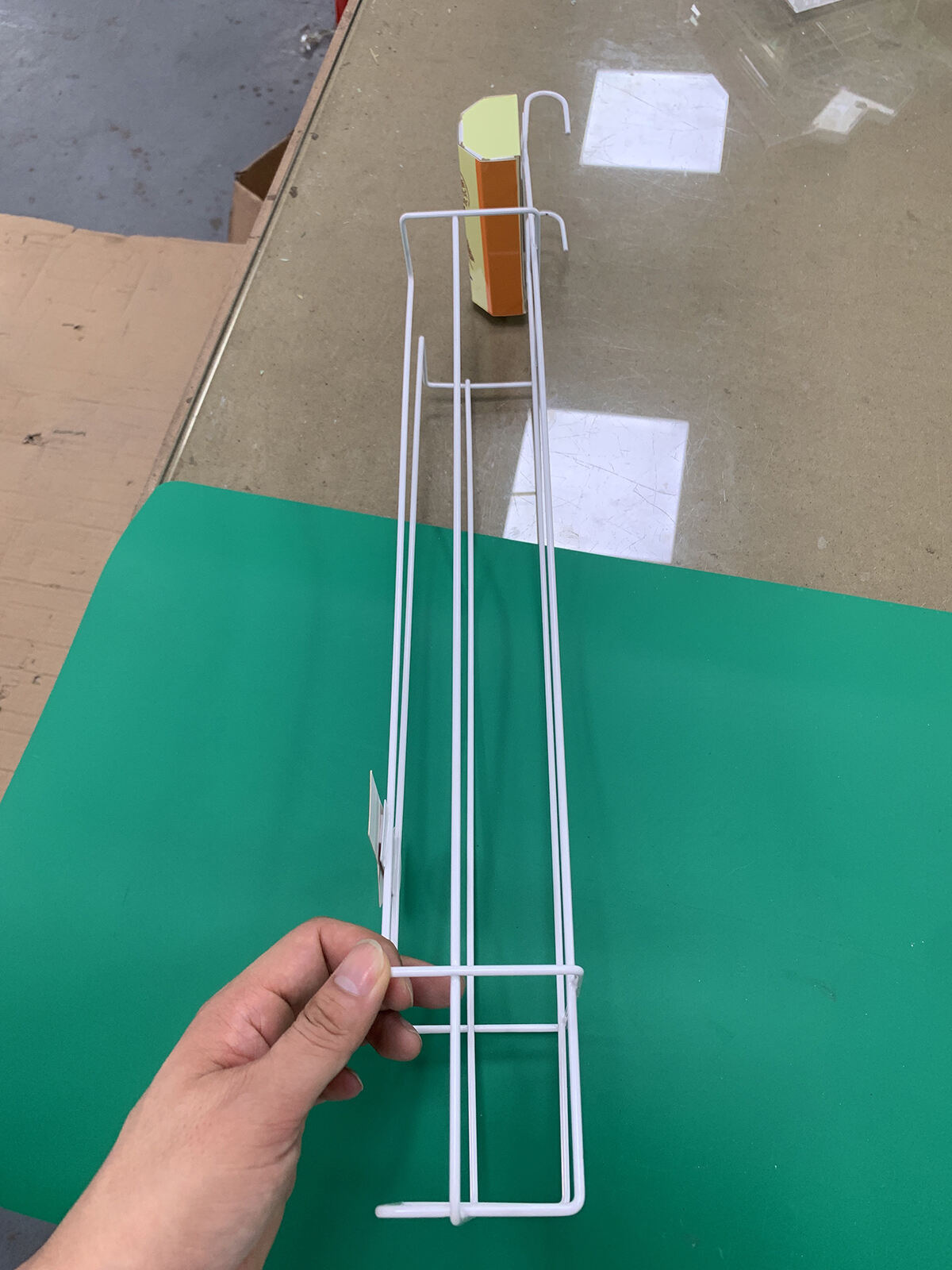

The hanging display stand mold represents a crucial manufacturing tool designed for creating versatile retail display solutions. This precision-engineered mold enables the production of durable and aesthetically pleasing display stands that can be suspended from various surfaces. The mold incorporates advanced injection molding technology, featuring carefully calculated gates, runners, and cooling channels to ensure optimal material flow and product quality. Its design accommodates multiple cavity configurations, allowing for efficient mass production while maintaining consistent quality across all units. The mold's structure includes sophisticated venting systems and precise temperature control mechanisms, ensuring the final products are free from defects and meet strict quality standards. These molds are specifically engineered to produce display stands capable of supporting various weights while maintaining structural integrity. The technology enables the creation of complex geometries and integrated mounting points, essential for modern retail display requirements. Applications span across retail environments, trade shows, commercial spaces, and marketing installations, offering versatile solutions for product presentation and brand visibility.