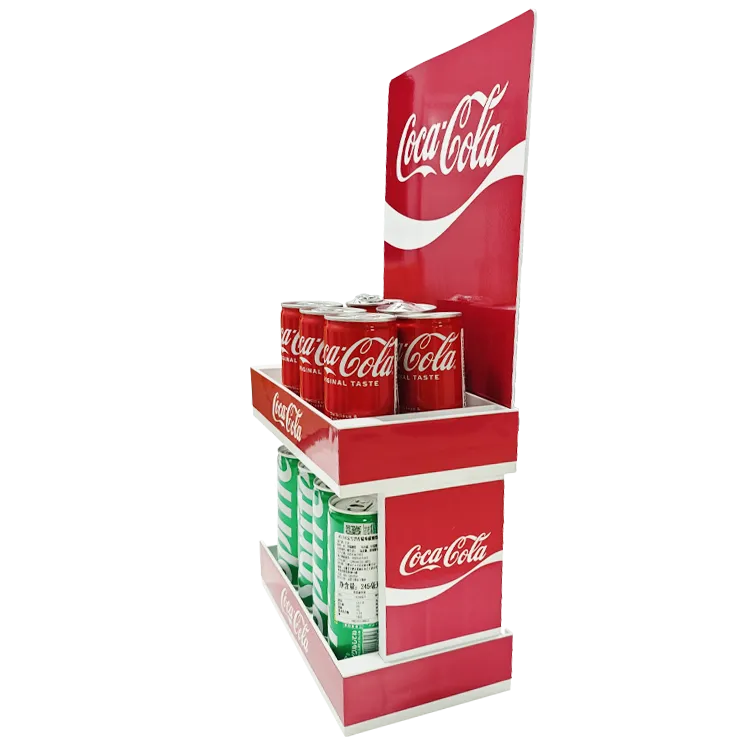

Injection molded plastic combination desktop display stand engineered for controlled press-fit assembly. Designed by an experienced retail POP display manufacturer for FMCG beverage, snack, candy, and chocolate displays.

| Brand | DP | Packaging | Customize | |

| Size | L10.63×W5.51×H17.52inches | Material | Plastics | |

| Colour | Customize | Place of Origin | China | |

| Productivity | 2000 pieces per month | Transportation | Ocean,Land,Air,Express | |

| Supply Ability | 200 of 40 feet container size | Code | ||

| Port | Shenzhen,Hong Kong,Guang Zhou | Payment Type | L/C | |

| Incoterm | FOB、EXW | Package Type | Custom Printed Display Boxes with Logo | |

| Sales Unit | Piece/Pieces |

Product Details

This plastic combination desktop display stand is developed based on injection molded components assembled through press-fit insertion, a structure that requires higher manufacturing precision than visually assembled displays.

In press-fit designs, the key challenge is not whether parts can be inserted, but whether insertion force, dimensional tolerance, and material elasticity remain consistent across mass production. Each molded component must achieve a balance between secure locking and damage-free assembly.

From an injection molding perspective, insertion structures require strict control over:

wall thickness uniformity to prevent stress concentration during insertion,

shrinkage rate consistency to ensure stable interference fit,

and edge chamfer design to guide smooth insertion without deformation.

If these factors are not properly managed, press-fit parts may experience cracking, whitening, loosening, or inconsistent assembly feel during installation. This is why press-fit structures are treated as a manufacturing system problem, not just a structural design choice.

For desktop retail environments, stable press-fit assembly ensures that the display maintains its form under frequent product loading and customer interaction. This makes it suitable for counter pop display applications while supporting various FMCG categories such as candy pop display, snack pop display, and compact beverage pop display solutions.

As a custom pop display manufacturer, we integrate insertion force testing and tolerance validation into the mold development stage. This ensures that every component fits precisely after molding, allowing fast assembly while maintaining long-term structural reliability in real retail scenarios.

The combination structure also supports scalability. While the final product appears compact, the underlying logic aligns with a modular pop display system, enabling future extensions or layout adjustments without reengineering the entire mold.

FAQ

What is press-fit assembly in plastic retail displays?

Press-fit assembly refers to inserting injection molded components together using controlled interference, without screws or adhesives.

What is the biggest risk of press-fit structures?

The main risk is inconsistent insertion force caused by dimensional variation, which can lead to cracking, loosening, or unstable assembly.

How is insertion force controlled during manufacturing?

Insertion force is controlled through mold precision, material selection, shrinkage compensation, and post-molding dimensional inspection.

Why is press-fit more challenging than snap-fit?

Press-fit relies heavily on material elasticity and tolerance accuracy, while snap-fit allows more structural flexibility through locking geometry.

Can press-fit displays withstand repeated use?

Yes, when designed correctly, press-fit structures maintain stability under repeated loading, making them suitable for long-term FMCG retail use.

Is this display limited to desktop use only?

Primarily yes, but the press-fit logic can also support compact floor pop display structures depending on configuration.

How does press-fit assembly improve visual quality?

Without visible fasteners or hardware, press-fit assembly delivers a cleaner appearance ideal for premium FMCG branding.

What types of products are best suited for this display?

This structure works well for lightweight packaged products such as candy, snacks, chocolate, and small beverage items.

Copyright © 2026 Shanghai FuLi Industry & Trade Co., Ltd. All rights reserved. Privacy policy