Global retail expansion presents unprecedented challenges when implementing large-scale display rollouts across diverse markets. Companies investing millions in visual merchandising infrastructure must navigate complex supply chain logistics, cultural preferences, and operational constraints while maintaining brand consistency. The strategic deployment of acrylic display stands has emerged as a critical component in successful retail expansions, offering versatility and durability that traditional display solutions cannot match. Understanding the execution risks inherent in global rollouts enables retail leaders to develop comprehensive mitigation strategies that protect investments and ensure seamless brand experiences across all locations.

Strategic Planning for Display Infrastructure Deployment

Market Assessment and Cultural Adaptation

Successful global retail display rollouts begin with comprehensive market assessment that extends beyond basic demographic analysis. Regional preferences for visual merchandising vary dramatically across cultures, influencing how consumers interact with acrylic display stands and product presentations. Market research must evaluate local shopping behaviors, space utilization patterns, and aesthetic preferences to inform display selection and positioning strategies. This foundational analysis prevents costly misalignment between display infrastructure and consumer expectations in target markets.

Cultural adaptation requirements often necessitate modifications to standard display configurations while maintaining brand integrity. Acrylic display stands offer exceptional flexibility in this regard, allowing for customization of dimensions, transparency levels, and mounting systems to accommodate regional preferences. Understanding local regulations regarding retail fixtures, safety standards, and accessibility requirements ensures compliance while avoiding deployment delays that can derail rollout timelines and budget projections.

Infrastructure Compatibility and Technical Requirements

Technical infrastructure compatibility represents a critical success factor often underestimated in global rollout planning. Existing store layouts, electrical systems, and structural limitations vary significantly across international locations, requiring careful evaluation before finalizing display specifications. Acrylic display stands must integrate seamlessly with existing infrastructure while accommodating future expansion needs and technology upgrades that may be implemented during the rollout period.

Standardization protocols balance consistency requirements with local adaptation needs, creating frameworks that ensure brand coherence while allowing necessary flexibility. Documentation of technical specifications, installation procedures, and maintenance requirements enables consistent implementation across diverse teams and locations. This systematic approach reduces execution risks associated with miscommunication and ensures that acrylic display stands function optimally regardless of geographic location or local installation expertise.

Supply Chain Risk Mitigation Strategies

Vendor Selection and Quality Assurance

Vendor selection processes for global display rollouts require evaluation criteria that extend beyond traditional cost and quality metrics. International suppliers must demonstrate consistent quality control across multiple production facilities, reliable logistics capabilities, and responsive support systems that can address issues promptly across time zones. Acrylic display stands sourced from qualified manufacturers should undergo rigorous testing protocols that verify durability, aesthetic consistency, and performance under various environmental conditions encountered in global retail environments.

Quality assurance programs must incorporate inspection protocols at multiple stages of the production and distribution process. Pre-production samples, in-process quality checks, and final inspection procedures ensure that acrylic display stands meet specifications before shipment to international destinations. Establishing clear quality standards and acceptance criteria prevents costly returns, installation delays, and brand image damage that can result from substandard display components reaching retail locations.

Logistics Coordination and Timeline Management

International logistics coordination requires sophisticated planning that accounts for customs procedures, shipping delays, and local delivery challenges that vary across markets. Acrylic display stands must be packaged and shipped using methods that protect product integrity while optimizing transportation costs and delivery schedules. Buffer time built into rollout timelines accommodates unexpected delays while maintaining critical path milestones that ensure coordinated store openings and promotional campaigns.

Distribution strategy development considers regional warehousing capabilities, local delivery networks, and inventory management systems that support ongoing operations beyond initial installation. Establishing strategic inventory positions reduces lead times for replacement components and supports rapid response to unexpected demand fluctuations or damage issues that may arise during the rollout process. This proactive approach ensures that acrylic display stands remain available when needed throughout the deployment timeline.

Installation and Deployment Excellence

Team Training and Standardization

Installation team training programs ensure consistent deployment quality regardless of geographic location or local contractor capabilities. Standardized procedures for acrylic display stands installation, positioning, and initial configuration create repeatable processes that minimize variability and reduce execution risks. Training materials must account for language barriers, varying skill levels, and different tool availability across international markets while maintaining safety standards and quality expectations.

Certification programs validate installation team competencies before deployment begins, reducing the likelihood of costly rework or safety incidents during rollout execution. Video-based training modules, hands-on workshops, and competency assessments ensure that teams understand proper handling techniques, assembly procedures, and quality standards for acrylic display stands. This investment in human capital development pays dividends through improved installation quality and reduced support requirements during and after deployment.

Quality Control and Performance Monitoring

Real-time quality control systems enable immediate identification and correction of installation issues before they impact multiple locations or compromise rollout schedules. Mobile inspection applications, photographic documentation requirements, and standardized checklists ensure that acrylic display stands meet specifications and perform as intended in each retail environment. This systematic approach prevents the accumulation of minor issues that can become major problems if left unaddressed.

Performance monitoring extends beyond initial installation to encompass ongoing functionality assessment and maintenance needs identification. Regular inspections of acrylic display stands in operational environments provide valuable feedback for future rollouts while ensuring that current installations continue meeting performance standards. Data collected through these monitoring activities informs continuous improvement initiatives and helps optimize future deployment strategies.

Technology Integration and Future-Proofing

Digital Integration Capabilities

Modern retail environments increasingly require display solutions that integrate seamlessly with digital technologies and smart store systems. Acrylic display stands must accommodate sensors, lighting systems, and interactive elements while maintaining aesthetic appeal and structural integrity. Forward-thinking deployment strategies consider current technology requirements alongside anticipated future developments that may require display modifications or upgrades during the operational lifecycle.

Technology integration planning addresses power requirements, connectivity needs, and maintenance access for digital components incorporated into display systems. Acrylic display stands offer advantages in this regard through their transparency, which allows for discrete integration of wiring and electronic components without compromising visual appeal. This capability supports current technology implementations while providing flexibility for future enhancements as retail technology continues evolving.

Scalability and Adaptation Framework

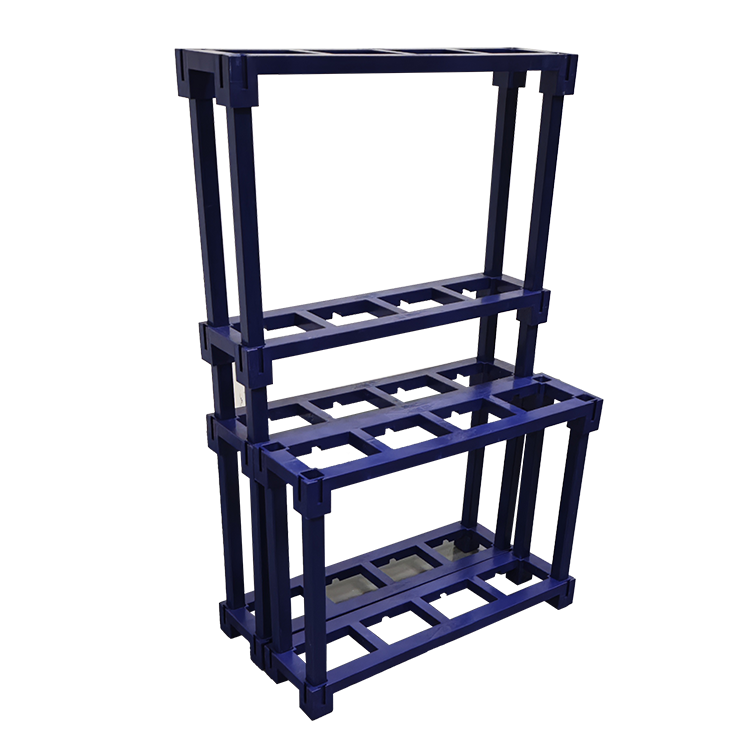

Scalability considerations ensure that initial display deployments can accommodate business growth and market expansion without requiring complete infrastructure replacement. Modular acrylic display stands systems enable incremental expansion and reconfiguration as retail space requirements evolve. This flexibility reduces long-term costs while supporting business agility in dynamic retail markets where consumer preferences and competitive pressures drive frequent changes.

Adaptation frameworks provide structured approaches for modifying display configurations in response to changing business needs or market conditions. Standardized connection systems, interchangeable components, and documented modification procedures enable efficient updates to acrylic display stands without disrupting ongoing operations. This capability proves essential for maintaining competitive positioning in markets where rapid response to consumer trends and competitive actions determines success.

Cost Management and ROI Optimization

Budget Planning and Cost Control

Comprehensive budget planning for global display rollouts must account for direct costs, indirect expenses, and contingency requirements that may arise during implementation. Acrylic display stands represent a significant capital investment that requires careful cost analysis including procurement, shipping, installation, and ongoing maintenance expenses. Detailed cost models enable accurate financial planning while identifying opportunities for optimization through strategic sourcing, efficient logistics, and standardized installation procedures.

Cost control mechanisms monitor spending against approved budgets while providing early warning of potential overruns that could impact project viability. Regular financial reviews assess actual costs against projections, enabling corrective actions before budget variances become unmanageable. This disciplined approach ensures that acrylic display stands deployments deliver expected value while maintaining financial accountability throughout the rollout process.

Return on Investment Measurement

ROI measurement frameworks establish baseline performance metrics and tracking systems that quantify the business impact of display infrastructure investments. Sales performance, customer engagement levels, and operational efficiency improvements attributable to acrylic display stands must be measured consistently across all locations to validate investment decisions. This data-driven approach supports future investment planning while demonstrating the value creation potential of strategic display deployments.

Long-term value assessment considers operational cost savings, maintenance efficiency, and adaptability benefits that extend beyond immediate sales impact. Acrylic display stands often deliver superior total cost of ownership through reduced maintenance requirements, improved durability, and enhanced flexibility compared to traditional alternatives. Comprehensive ROI analysis captures these benefits while providing insights that inform future rollout strategies and investment priorities.

FAQ

What are the most critical risks in global retail display rollouts?

The most critical risks include supply chain disruptions that delay installations, quality variations that compromise brand consistency, cultural misalignment that reduces consumer engagement, and cost overruns that threaten project viability. Acrylic display stands help mitigate several of these risks through their durability, adaptability, and consistent manufacturing quality when sourced from reputable suppliers.

How can companies ensure consistent quality across international installations?

Consistent quality requires standardized specifications, comprehensive training programs, rigorous quality control processes, and reliable supplier partnerships. Companies should establish clear performance standards for acrylic display stands, implement certification programs for installation teams, and maintain ongoing monitoring systems that identify and address quality issues promptly across all locations.

What factors should influence the selection of display suppliers for global rollouts?

Supplier selection should consider manufacturing capacity, quality control systems, international logistics capabilities, technical support availability, and financial stability. For acrylic display stands, additional factors include material quality certification, customization capabilities, lead time reliability, and experience with similar large-scale deployments in relevant markets.

How can retailers balance standardization with local market adaptation needs?

Effective balance requires flexible design frameworks that maintain core brand elements while allowing customization for local preferences and requirements. Acrylic display stands offer excellent flexibility through modular designs, adjustable configurations, and customizable dimensions that enable adaptation without compromising brand consistency or operational efficiency across global retail networks.

Table of Contents

- Strategic Planning for Display Infrastructure Deployment

- Supply Chain Risk Mitigation Strategies

- Installation and Deployment Excellence

- Technology Integration and Future-Proofing

- Cost Management and ROI Optimization

-

FAQ

- What are the most critical risks in global retail display rollouts?

- How can companies ensure consistent quality across international installations?

- What factors should influence the selection of display suppliers for global rollouts?

- How can retailers balance standardization with local market adaptation needs?