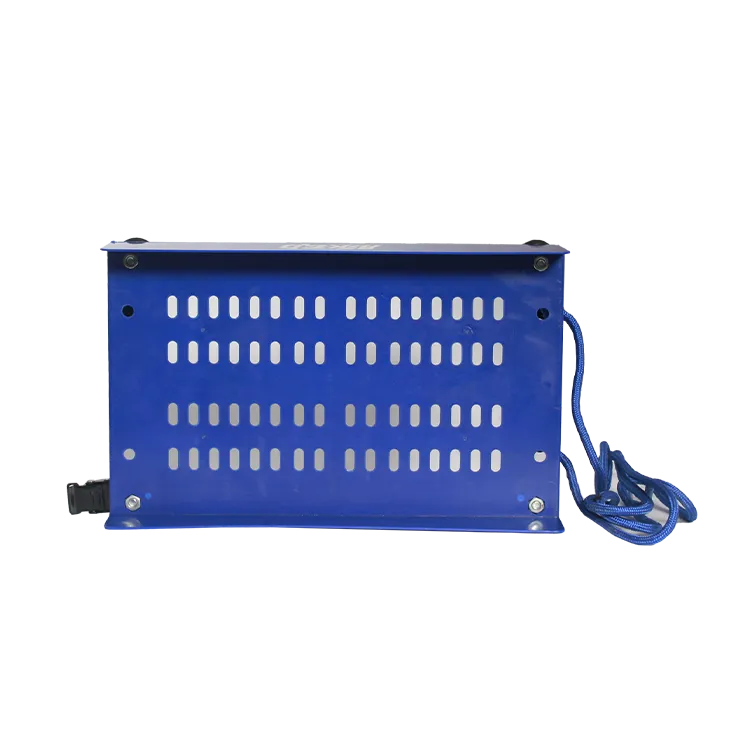

Custom injection molded beverage crate floor display with casters, engineered for stable load-bearing and long-lasting performance. Ideal for FMCG product visibility, mobility, and in-store display solutions.

| Brand | DP | Packaging | Customize | |

| Size | L15.75×W9.65×H2.99inches | Material | Plastics | |

| Colour | Customize | Place of Origin | China | |

| Productivity | 2000 pieces per month | Transportation | Ocean,Land,Air,Express | |

| Supply Ability | 200 of 40 feet container size | Code | ||

| Port | Shenzhen,Hong Kong,Guang Zhou | Payment Type | L/C | |

| Incoterm | FOB、EXW | Package Type | Custom Printed Display Boxes with Logo | |

| Sales Unit | Piece/Pieces |

Product Details

This beverage crate floor display box is a high-strength, injection molded solution specifically designed for FMCG retail environments where both mobility and load-bearing stability are critical. The display integrates reinforced plastic walls and caster mounting points, engineered to endure heavy product loads while allowing smooth movement across store floors.

The key challenge in this design is balancing structural integrity with mobility. Casters introduce dynamic stress, and frequent repositioning can accelerate wear. To address this, the injection molding process incorporates uniform wall thickness, rib reinforcement, and stress-distribution design around caster attachments. These features ensure that the molded components resist cracking, warping, or loosening during repeated use.

Material selection is critical. High-performance plastics such as ABS or PP blends are used for their impact resistance, dimensional stability, and long-term durability. The caster sockets are precision-molded to maintain tight tolerances, preventing wobble while allowing smooth rotation.

This design is suitable for a wide range of products, including beverage pop display, candy pop display, chocolate pop display, and snack pop display. Its robust structure allows it to serve as a floor pop display or, with minor configuration adjustments, as a low-height counter pop display. The modular design also supports integration into a modular pop display system, enabling scalable merchandising layouts.

By collaborating with a custom pop display manufacturer, brands gain access to advanced injection molding and assembly expertise, ensuring every display meets stringent durability and performance requirements while maintaining aesthetic appeal. The result is a reliable, easy-to-install, and visually effective display for FMCG retail campaigns.

FAQ

Q: How is load-bearing performance ensured in this display?

A: Through reinforced wall structures, ribbing, and optimized wall thickness, ensuring that the floor display can support multiple beverage crates without deformation.

Q: How are caster-mounted injection molded components made durable?

A: Caster mounts are precision-molded with stress-relief features and tested for repeated dynamic loads to prevent cracking or loosening over time.

Q: What materials are used for mobility and strength?

A: High-strength plastics like ABS or PP blends are chosen for their impact resistance, dimensional stability, and long-term durability.

Q: Can this display withstand frequent repositioning in stores?

A: Yes, the combination of reinforced molding and durable casters ensures smooth movement and structural integrity even under repeated rolling.

Q: Is this display suitable for multiple FMCG product types?

A: Absolutely. It accommodates beverages, candy, snacks, chocolate, and more, supporting both floor pop display and counter pop display setups.

Q: How does mold design impact caster performance?

A: Molded caster sockets are engineered with precise tolerances and optimized geometry to reduce stress concentration, ensuring smooth rotation and long-lasting functionality.

Q: Can this display be integrated into larger merchandising systems?

A: Yes. Its modular design allows seamless integration into a modular pop display system for cohesive store layouts.

Copyright © 2026 Shanghai FuLi Industry & Trade Co., Ltd. All rights reserved. Privacy policy