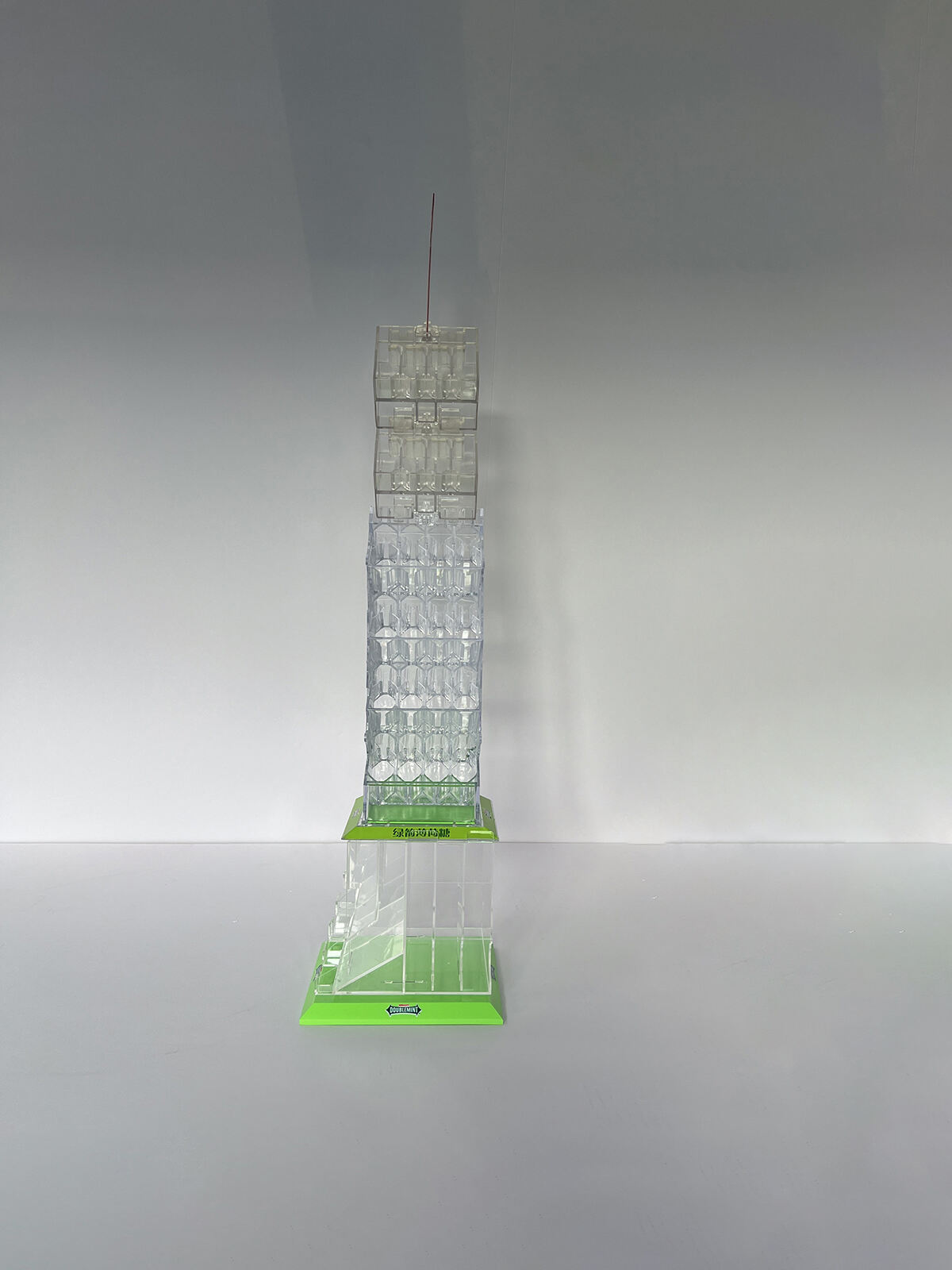

custom metal display rack mold

The custom metal display rack mold represents a crucial manufacturing component designed to produce high-quality retail display solutions. This precision-engineered tool enables the consistent production of metal display racks with exact specifications, ensuring uniform quality and structural integrity. The mold incorporates advanced engineering principles to facilitate efficient mass production while maintaining exceptional detail accuracy. It features carefully calculated injection points, cooling channels, and release mechanisms that work together to create durable, aesthetically pleasing display rack components. The mold's design accommodates various metal types and thicknesses, allowing for versatile application across different retail environments. Its modular construction permits easy maintenance and part replacement, reducing downtime and extending operational lifespan. The mold's surface treatment ensures optimal material flow and prevents common defects like warping or incomplete filling. Additionally, the design includes provisions for different finish options, enabling manufacturers to meet diverse client specifications. This versatility makes it ideal for producing display racks for retail stores, supermarkets, exhibitions, and commercial spaces.